Dramatic changes occur when the Olympics

come to town. For Salt Lake City, the host of the XIX Olympic Winter Games in

2002, the summer of 1999 is the season of construction. Some of the best people

in the design and construction businesses have gathered in Utah to create master

plans, develop facility designs, and manage construction under the purview of

the permanent venue construction team assembled by the Salt Lake Organizing

Committee (SLOC). After all, you only get one shot at the Olympics—whether

you’re an athlete or an engineer.

Dramatic changes occur when the Olympics

come to town. For Salt Lake City, the host of the XIX Olympic Winter Games in

2002, the summer of 1999 is the season of construction. Some of the best people

in the design and construction businesses have gathered in Utah to create master

plans, develop facility designs, and manage construction under the purview of

the permanent venue construction team assembled by the Salt Lake Organizing

Committee (SLOC). After all, you only get one shot at the Olympics—whether

you’re an athlete or an engineer.

Although some of the venues for the 2002 Olympics already exist, three sites

in particular are either being built from scratch or will replace outdated or

unusable facilities. The three venues couldn’t be more different. One involves

converting pastureland into a world-class cross-country skiing and biathlon

course. Another includes building two ski jumps that share a common landing area

on the side of a mountain. The third will serve as an icon for the Olympics—a

$23.2-million, 255,000 sq ft (23,690 m2) speed-skating facility covered by a

cable-suspended roof, one of the first buildings in the American West to feature

such a design.

The three permanent venues being constructed for

the Olympics could become grand dramatic statements, but the SLOC wants to make

simple statements, says Ranch Kimball, the SLOC’s director of permanent venue

construction.

Several factors are driving Olympic facility design

and construction in Salt Lake City: The venues must meet Olympic competition

requirements and be suitable afterward to serve as world-class training

facilities and provide public recreation. Athletic needs, aesthetic details, and

environmental considerations are all woven into the design plans, says Grant

Thomas, a vice president in the buildings and infrastructure group at Bechtel

who took a leave of absence to become the SLOC’s senior vice president for

venues.

The 250 acre (100 ha) Soldier Hollow cross-country skiing

and biathlon course, which is being built in Wasatch Mountain State Park, is the

most important venue simply because it will host the greatest number of Olympic

events. “Most Olympic facilities in the world are either devoted to

cross-country or biathlon—the dual approach is unique,” says Kevin Jardine, the

SLOC project manager for Soldier Hollow. The agriculturally based Heber Valley,

about 45 mi (72 km) from downtown Salt Lake City, will offer up 22 medal events

over the course of 16 days at a converted sheep and cow pasture—a perfect

setting. It’s perfect because the course requirements for Olympic competition

are so rigid there are practically no other feasible sites available.

The venue must be located below 5,900 ft (1,800 m). It must also include

specific slope gradients and precise lengths and categories of hills. Exact

percentages must govern the relationships between flat, hilly, and undulating

terrain, and the venue must meet requirements for the positions along the course

where certain hills of certain grades and lengths should occur, says John

Aalberg, the director of cross-country for the SLOC and a former Olympic

athlete. “The project is a lot more complex than we originally thought,” Aalberg

says. Instead of working with the terrain to determine the course, the designers

are working with a list of requirements and trying to make the land conform to

the list.

EDAW

INC. |

As Salt Lake City, top, prepares for the 2002 Olympics, construction begins on three sites that must serve as public facilities when the games are through. The cross-country and biathlon venue, left, covers 250 acres (100 ha) and is being constructed in Wasatch Mountain State Park. More than 14 mi (23 km) of trails will be built for 22 events. To reduce the footprint of the site, the trail system uses many crossovers and loops so races with different lengths can be run on the same course. |

On top of all the requirements, 18 course designs, ranging in length from 0.9

to 31 mi (1.5 to 50 km), needed to be configured on 14 mi (23 km) of constructed

trails. Many loops and crossover trails have been designed into the maze to

accommodate different distances. “It’s like a very complex jigsaw puzzle,” says

Phil Hendricks, Jr., a senior associate at EDAW in Fort Collins, Colorado, which

is providing land planning and design services for the project.

Construction of permanent facilities will cost about $9 million and will

include four bid packages: trails, the site stadium area and utilities, an 8,000

sq ft (743 m2) competition management building, and a snowmaking system. Stable

natural snowfall is questionable at this altitude in Utah, so a $1.5-million

snowmaking system will be installed. The trails also are oriented to minimize

snowmelt; wherever possible trail designers avoided south-facing pitches. To

transport water to the site for snow, the SLOC agreed to contribute $1 million

toward the construction of a $6-million pressurized irrigation system for local

farmers. The SLOC will tap into that system and build a 2 million gal (7,570 m3)

water storage pond for making snow.

| Because not many contractors in the world have built ski trails, all

of the contractors are being prequalified. The contracts are based on a

guaranteed maximum price, and bonus clauses allow contractors to share a

percentage of leftover funds once the project is completed. The trails

contract has been awarded to W.W. Clyde & Company, of Springville,

Utah. International cross-country skiing competition requires a trail width of at least 16.4 ft (5 m). “It’s more like a road,” Aalberg says. Even so, the trails contractor has to understand that the trails are not roads and don’t necessarily have to be flat and straight. “If there’s a rock in the way, we would rather go around it than move it,” Aalberg says. |

SWECO INTERNATIONAL |

About 110,000 cu yd (84,128 m3) of earth will be moved, but course designers

are still trying to follow the natural terrain, partly to minimize cut-and-fill

requirements. Retaining walls will be required in about a dozen locations to

stabilize slopes that have been disturbed, says Paul Taylor, a principal of

Bingham Engineering in Salt Lake City, which is providing civil engineering

design services at Soldier Hollow. Most of the grading is being done around the

stadium area and the level shooting range for

the biathlon. Numerous

culverts and drainage systems are being installed to keep water off the course.

The openness of the site makes it extremely spectator friendly.

“It’s probably one of the best sites in the world,” Jardine says. Even so,

television broadcasters, which are footing a large sum of the construction costs

for rights to the games, have requested a tree-lined finish site, so more than

2,000 trees will be transplanted to the sagebrush-covered mountainside. Some

will be used to shade the trails, which will help keep the snow from melting. A

pedestrian bridge over the competition area will enable spectators to enter the

stadium area during races. The SLOC expects construction to be completed by

November 2000.

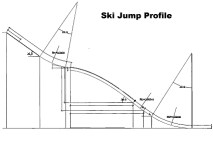

Just up the road from Soldier Hollow but at a

significantly higher elevation is the Utah Winter Sports Park, in Park City. The

bobsled and luge facilities were built in 1995, but construction of world-class

ski jumps, which will cost in excess of $10 million, continues. The Olympic ski

jumps for the XIX Games will include two sizes: the K-120 and the K-90. These

roughly relate to the maximum distance, in meters, that the jumpers fly. The

critical point K is the point at which the landing hill begins to curve away

from the downward slope (see figure).

Although the Winter Sports Park originally had a K-90 jump, it

did not meet Olympic standards and had to be removed. “If we built the one

hundred and twenty meter jump near the existing ninety meter takeoff point,

jumpers would be more exposed to crosswinds from the ridgeline,” adds Peter

Emerson, the executive officer of operations for Edwards & Daniels

Architects in Salt Lake City. The designers reconfigured the jumps by moving

them 23 ft (7 m) into the mountainside to maintain the ridgeline, which will now

act as a wind buffer. “It’s like putting in a runway—you don’t want crosswinds,”

says Arnie Nishioka, the project’s civil engineer of record, who works for

Holmes & Narver in Salt Lake City.

By configuring the

parallel ski jumps into the existing hill, the venue should blend in better with

the natural landscape. A 150 ft (46 m) tall ski jump tower, a height common in

Europe, could have become an obtrusive landmark, says Marty Volla, the SLOC’s

ski jump project manager. Instead, he says they “sort of carved [the jumps] into

the hill.” Also, jumps that are close together can share a common outrun,

minimizing on-hill construction.

Excavation material, more than

440,000 cu yd (12,460 m3) of it, was used to extend and counterslope the outrun

area for the jumpers and provide a foundation for temporary bleachers that will

seat about 20,000 spectators during the Olympics. The material was compacted to

a relative density of about 90 percent. Between 80,000 and 100,000 cu yd (61,184

and 76,480 m3) of rock had to be blasted from the site, Nishioka says.

Aside from the steep slope, the project presents a geometric

challenge involving compound radii. The critical points relate to established

formulas for ski jumps used for international competition. The angle and

placement of the hill in relation to wind currents, as well as the profile of

the hill between takeoff and landing, are left up to the designer. Computer

programs were used to determine the best alignments and hill placements. The

jumps will be no higher than 10 ft (3 m) from the ground and jumpers will be no

more than 15 to 20 ft (4.6 to 6 m) above the surface during their flights. The

profile of the ski jump and landing hill basically follows the flight of the

jumper.

JACOBSEN

CONSTRUCTION |

More than 440,000 cu yd (12,460 m3) of material has been excavated from the ski jump. Most of it is being used for fill around the outrun area, where temporary spectator seating will be built. |

“The challenge is to understand ski jumps—it’s new to all of us,” says Volla.

To learn more about ski jump design, the SLOC brought international expertise on

board, including renowned ski jump designer Kurt-Evan Sonehag of SWECO

International in Falun, Sweden. The design team also made a trip to several

world-class ski jumping facilities in Europe and Japan.

All the

jumps around the world have drainage problems, Emerson says. Because natural

springs would dump water onto the landing hill and outrun at the Winter Sports

Park, 12 in. (300 mm) perforated pipe is being used to divert the runoff. Also,

a gravel base beneath the concrete landing hill will act as a capillary water

barrier, and a trench drain at the end of the concrete outrun will collect

sheeting water.

Because the jumping facility is located on a 35

degree slope, the question of constructibility arose. The number one concern is

keeping the jump and landing hill from sliding down the mountain, says Greg

Brickey, a principal of Brickey Design Associates in Scottsdale, Arizona, and

the structural engineer of record for the project. Both jumps are similar in

design and share a common U point, which is where the landing hills end and the

common outrun begins. The K-120 is higher and located farther up the

mountainside than the K-90 jump.

Tensioned rock anchors 15 to 25

ft (4.6 to 7.6 m) long driven into bedrock hold 7 ft (2.1 m) high and 16 ft (4.9

m) long concrete piers in place. The large jump has 11 piers and the smaller, 9.

The piers are covered with about 4.5 ft (1.4 m) of backfill, which leaves about

2.5 ft (0.8 m) of pier above the surface. Steel bents on top of the piers

support steel girders that run the length of the jump and connect the piers. A 3

in. (76 mm) metal deck and 8 in. (200 mm) of reinforced concrete form the ski

jump surface. Guide boards similar to curbs will create a trough for about 18

in. (457 mm) of snow.

Because the facility will be used for

summer jumping, a slick plastic jumping surface will be installed on the

concrete. A snow net must then be placed on the jump and landing hill in winter

to keep snow from sliding off the hill. The snow net helps create friction

between the snow and the surface of the jumps and landing hills. A major problem

with the steep slopes for ski jumping is what’s known as losing the hill.

Six inch (150 mm) reinforced slabs on grade will make up the

landing hills. To keep the landing hills in place, Jacobsen Construction

Company, of Salt Lake City, is installing grade beams that are tied into

bedrock. The beams are placed 30 ft (9 m) on center across the landing hill. A

special mix of concrete—a little drier than usual—will be pumped on-site and

screeded quickly with special equipment to keep it from sliding down the

mountain. A large tower crane installed about midway up the hill and two crawler

cranes—one on top and one at the bottom—are moving all of the materials into

place. In all, about 370 tons (336 Mg) of steel and 5,400 cu yd (4,130 m3) of

concrete will be used.

Although the site is located in Park City,

which typically gets a lot of snow, the SLOC is putting in a snowmaking system

just in case. “We don’t know what God is going to provide us with in 2002 so we

have to have snow making,” Volla says. The SLOC is aiming for a fall 2000 finish

date.

Viewed from the top of the K-120 jump, the ski jumpers will

appear to fly into the valley. It’s 430 ft (131 m) from the start house to the

outrun, which is higher than any office building in Salt Lake City.

| Meanwhile, on the city’s west side, the SLOC is designing the Oquirrh

Park Speed Skating Oval, which it hopes will house the fastest ice in the

world. The facility will be covered with a cable-suspended roof, which

will reduce the inside volume of the building and, consequently, the

heating and cooling costs. The structural design of the building is a

collaboration between Ove Arup and Partners, of New York City, which is

responsible for the arena portion, and Martin/Martin-Utah, of Salt Lake

City, which is designing other parts of the building. The architect is

Gillies Stransky Brems Smith, of Salt Lake City. Because the temperature,

both of the ice and of the air inside the building, is extremely important

during athletic competitions, the SLOC decided that the smaller the

building envelope, the easier it would be to maintain consistent

temperatures. |

The cable suspended roof has less than half the amount of steel that would have been used on a steel truss system. Less steel means less weight, which makes the roof susceptible to wind loads. |

| The

cable-suspended roof for the Oquirrh Park Speed Skating Oval consists of a

310 ft (94 m) span supported by 12 pairs of 109 ft (33 m) tall masts, a

3.5 in. (90 mm) diameter main cable, and angled hangers connected to a 36

in. (914 mm) deep steel girder inside the

building. |

|

| Back to August 1999 CE Magazine Table of Contents |